Investigating Ceramic Coatings with THz Imaging

Department of Applied Sciences and Mechatronics, Munich University of Applied Sciences

Menlo Systems, Martinsried

Authors: Patrizia Krok (Menlo Systems), Prof. Datong Wu (Munich University of Applied Sciences)

Contact email address: p.krok@menlosystems.com

Properties of ceramic composite materials

Fiber reinforced ceramic matrix composite (CMC) materials are known for excellent mechanical properties such as high elasticity and good fracture behavior, and also for their highly thermal and electrical insulating characteristics. They are therefore gaining importance as protective thermal barrier coatings (TBC) on mechanical parts which are exposed to excessive heat, such as is the case in gas turbines. Acting as thermal shielding, they keep a lower temperature at the base material and prevent its oxidation. Due to their low material density, CMCs have also the potential to decrease the overall weight of the technical parts. However, their manufacturing and quality test process is still challenging.

In order to achieve a well-defined thickness of 100 µm to few millimeters for the most common applications, the coating process needs to be carefully controlled. While the high porosity and low heat diffusivity of the CMC materials are fundamental for their scope of application, conventional methods of non-destructive testing (NDT) such as air-coupled ultrasound, x-ray tomography, or thermography fail in their characterization. Terahertz time domain spectroscopy (THz-TDS) and imaging provide a solution since they are capable of measuring the thickness of the coatings with high accuracy and also of detecting defects within the material. The THz technology has significantly advanced in the past years. The compact, flexible, and user friendly Tera Smart Terahertz spectrometer available from Menlo Systems is perfectly suited for the integration into manufacturing lines.

Measuring THz time-of-flight

Compared to conventional NDT techniques such as ultrasound, inspection with THz waves is contact-free and ideally suited even for porous materials, where the ultrasonic signal would be largely damped. CMCs are virtually transparent for THz radiation, such that the coating thickness on construction components can be measured with high accuracy. With THz imaging defects within the coating or at the interface to the substrate can be detected and visualized. Since THz radiation is strongly absorbed by water, moist areas are distinguished from dry. The water content can be determined quantitatively and the drying process can be monitored.

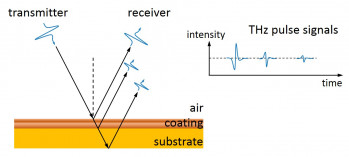

Figure 1: Schematic of the THz time-of-flight method illustrating the reflectivity at interfaces.

THz-TDS can be applied in transmission or reflection geometry. While measuring in transmission is sensitive to changes in absorption, the reflection mode offers free choice for substrate materials and offers a practicable solution for the most industrial applications. Similar to optical spectroscopy, THz-TDS is sensitive to the refractive index, with the reflectivity of an interface determining the amplitude and phase of a reflected THz signal. This makes it a suitable NDT technique for layered structures. From the time-of-flight (TOF) measurement using pulsed THz waves, the thickness of different layers can be derived with high accuracy in both, transmission and reflection mode (Fig. 1).

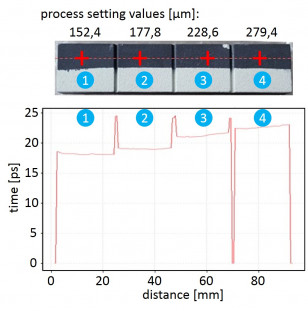

Figure 2: Top: Photo of a nickel-based super alloy sample coated with a layered TBC. Bottom: Profile of the interface reflection signal position recorded along the dashed line of the top picture.

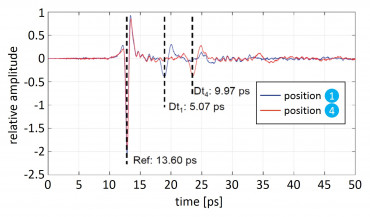

Figure 3: Temporal THz signal of the surface and interface reflections

Prof. Datong Wu from the Department of Applied Sciences and Mechatronics at Munich University of Applied Sciences elaborates different aspects of THz-TDS and documents the feasibility of the technique as a means for nondestructive testing of CMCs. All THz-TDS measurements in this work have been performed using Menlo Systems TeraSmart THz-TDS system. The angle of reflection was set to 30° with respect to the sample normal.

The first sample examined was Inconel coated by zirconia of varying layer thickness, the upper half was additionally sprayed with graphite (top of Fig. 2; sample provided by Siemens AG). Primarily, the coating thickness on areas 1 to 4 was determined in a TOF-measurement. The temporal THz signal of the surface reflection (reference) and the interface reflections (echo) at areas 1 and 4 are shown in Figure 3. From the time difference Dt between an echo reflection and the reference, the thickness of the coating is derived. Measuring along the dashed line marked in figure 2 gives the profile of the interface signal temporal position (bottom of Fig. 2). With a refractive index in the range of 4.5 to 5, the thickness of the four areas is estimated to 152.1 – 169.0 μm (1), 181.2 – 201.3 μm (2), 258.3 – 287.0 μm (3), and 299.1 – 332.3 μm (4). A calibration of the refractive index with a known sample would significantly increase the accuracy of the measurement.

A deconvolution algorithm for the reflectivity of thin layers

The described method is limited to thicker layers where the reflected THz signals of the surface and the interfaces can be separated in time. In thin layers and multilayered structures, however, those signals are overlapping. A specifically developed time-domain deconvolution algorithm for the measured reflectivity allows extending the application to thin multilayered structures: The sample reflectivity (signal) is cross correlated with the surface reflection signal (reference), then the time and amplitude of the maximum in the cross correlation are searched giving the first response peak. The peak multiplied with the reference is subtracted from the signal, yielding the residual signal which is the input for the subsequent iteration step. The loop outputs the sum of response peaks from which, together with the physical properties of the material, the thickness of each discrete layer is calculated.

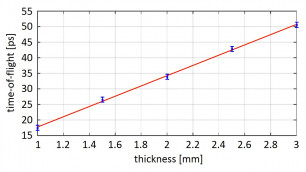

Figure 4: TOF-deconvolution of THz pulses at points of varying thickness in a ceramic composite sample (blue squares with error bars) and the linear model function (red line)

The algorithm was tested using two 0.68 mm thick silicon wafers separated by a thin air gap. The gap leads to two temporally overlapping reflection signals of opposite amplitude sign which is due to the corresponding refractive index changes. The algorithm clearly identified the two reflections. A second test was performed with CMC samples of stepwise varying thickness from 1 to 3 mm. The resulting time-of-flight deconvolution (Fig. 4) provides information for the exact thickness evaluation and confirms that the method is applicable for the investigation of layered CMC materials.

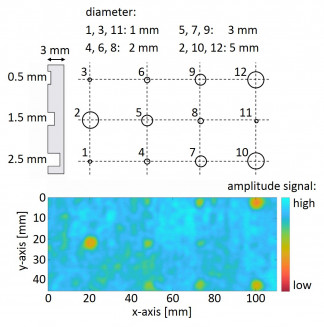

Figure 5: Layout of a ceramic sample with flat air channels of varying diameter and depth with the THz amplitude map of the reflection signal below.

THz imaging: deconvolution and image processing

In the third part of his work, Prof. Wu demonstrates how THz imaging is used to detect and analyze defects within or below a coating layer. For this purpose, a sample of aluminum oxide (Al2O3), a common ceramic material, was prepared with defects simulated by flat air channels of varying diameter and depth (top of Fig. 5, sample was provided by MTU Aero Engines). For data analysis ImageLab hyperspectral image processing software from Epina Softwareentwicklungs- und Vertriebs-GmbH has been used.

Each pixel of the image contains the amplitude and phase of the reflected THz signal and is evaluated by the deconvolution algorithm. The result is a map of the physical properties of the sample, such as internal boundaries, refractive index changes, or discontinuity. In the amplitude map, holes of 2 mm diameter and larger are clearly revealed (bottom of Fig. 5). The size of the THz focal spot and hence the image resolution are limited by increasing absorption of the high frequency spectral range by the sample material. A filtering function of the image processing software can be applied in order to isolate the contribution of different frequency components to the image and potentially increase the image resolution.

Publications:

D. Wu et al.: Application of Terahertz Time Domain Spectroscopy for NDT of Oxide-Oxide Ceramic Matrix Composites; Infrared Physics & Technology Vol. 102, 102995 (2019)

DOI: https://doi.org/10.1016/j.infrared.2019.102995

O. Peters, D. Wu: Investigating Ceramic Coatings with Terahertz Radiation; Photonics in Germany 2019, p. 40f